Here's how to replace wood balusters with iron and update stair railing without replacing it completely!

Want to update your staircase? Here is our tutorial on how to replace wooden balusters with iron the easy and cheap way!

Talk about a transformation from '90s to modern! Updating our railing and balusters has been one of the easiest and biggest transformations to move our house away from 1993 to 2017.

We updated our stairwell railings by sanding down the orange-tinted oak railings and staining them with Minwax Dark Walnut.

Then we replaced our stair spindles from white wood balusters to new iron ones and it's a totally different room!

If you want to update your staircase railing, check out the full tutorial below on how to replace stair spindles with wrought iron!

If you missed our past updates, here they are:

Week 1: the design plan

Week 2: how to save $$$ on house paint

Bonus: our beadboard ceilings

See the final hallway makeover reveal!

Click here to sign up for our weekly DIY newsletter!

Click here to grab our Home Renovation Planner and FINALLY get your next big DIY project organized!

How to Replace Wooden Balusters with Iron

Click here to pin this project to pinterest!

Tools needed:

How to remove wooden spindles

The first thing we did replacing our stair spindles was remove all of our old white wood balusters.

Using our awesome RYOBI One+ Cordless Reciprocating Saw, we cut an angled slice through each baluster and twisted them until they popped off.

The railing spindles were nailed in with a brad nailer, so we had to wiggle them until the nail came loose.

Then, we used an orbital sander to buff down the old orange-tinted oak finish on the railings.

We used three sander discs because of the amount of hidden gunk and sealant that was on these things and kept ruining the pads quickly.

We buffed them down all the way and then wiped everything with a damp rag.

The next step was to stain and seal the railings.

Like we said above, we used Minwax Dark Walnut that we have used on a ton of other projects and is basically the same color as our floors downstairs.

Be sure to check out our Dark Walnut by Minwax wood stain review!

This keeps a cohesiveness through the space and looks elegant.

Then we put five coats of matte polycrylic on the whole thing to keep them from getting warn down by people holding the railings.

How to install iron spindles

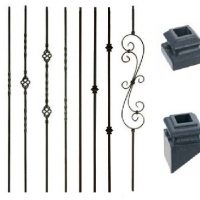

The last part of replacing stair spindles was that we added our new iron balusters. We ordered them on eBay for a great price.

There were tons of design options, but because the space was so small, we didn't want to have anything too elaborate. There's also tons of options on Amazon.

We opted to alternate two designs (a single swirly on one, a basket in between two swirlies on the other) that were fairly simple and wouldn't be distracting, yet were also elegant.

To add your own iron balusters, you need to cut them to size. Make sure to measure how deep the hole is in the railing, then how far the distance is between the railing and the bottom.

Add those together and cut your balusters from the center of your design to be that length.

For us, it was 30 inches. This is so you can slide the baluster up into the hole at the top, then drop it down to the board at the bottom.

Wondering how to cut iron balusters? We used our RYOBI reciprocating saw to cut the balusters to length.

They were easy to cut using a fine toothed saw blade. We marked the cuts by putting some Frog Tape where the cut should be and then buzzed it down.

Two things to remember when adding the balusters.

First, make sure you put the shoe on before you insert the baluster into the railing or you'll have to pull it back out.

The other is to use hot glue to hold them in place.

When researching what kind of glue to use for iron balusters, most places say to use epoxy. But, that makes it VERY permanent and is unnecessary.

Put some hot glue onto the end of the baluster, then insert it into the railing hole and adjust it down.

The glue will dry quick so don't mess around. Then put a little hot glue around the bottom of the railing and drop the shoe down to cover it up.

This is truly a transformation.

The project took a few days because there were several steps that required waiting (staining and sealing). But, it wasn't difficult.

The cutting and removing of the old balusters took about an hour for our space.

Sanding took an hour and installation of the new balusters took about two hours total.

It was a lot quicker after the first few when we got in a rhythm.

Updating our railing and balusters made the space look incredibly different and so much more modern.

Wondering how much iron balusters cost? Here's a cost breakdown:

Balusters - $16.66

2 x basket style @ $4.05 = $8.10

2 x single twist @ $2.30 = $4.60

4 x flat shoe @ $0.99 = $3.96

Other railing supplies (stain + sealant) had on hand

Iron balusters are also available at hardware stores like Lowes and Home Depot, but we found the best price on eBay.

**Note: this is just the cost for the railing and balusters at the top, since that hallway is what we are making over for the $100 Challenge.

We also updated the downstairs railings since we were already at it, but I didn't include that in this total. I hope that makes sense!

We wrote a whole post on the cost of replacing wood balusters with iron!

Click here to pin this project to your pinterest board!

I am loving all of the updates on this challenge and next be sure to check out the final reveal!

How to replace wood balusters with iron

Bored with your wooden staircase railing? Here is how to DIY upgrade your spindles with iron balusters!

Materials

- New iron balusters

- Hot glue or epoxy

- Stain

- Polycrylic

- Brush

Tools

- Reciprocating saw

- Orbital sander

Instructions

- Use reciprocating saw to cut wooden balusters in half.

- Pull out of each end and discard.

- Sand railing and stain or paint. Coat with poly to seal. Allow to dry.

- Measure the height for each spindle.

- Use reciprocating saw to trim iron spindles to height.

- Stick spindle up into top railing.

- Add glue or epoxy into lower hole.

- Stick spindle in that hole.

- Allow to dry, taping if necessary.

Notes

Each spindle might be a different length. Measure each.

Recommended Products

As an Amazon Associate and member of other affiliate programs, I earn from qualifying purchases.

Before you go...

Are you planning a full staircase makeover? You don't want to miss our step by step tutorials on how to replace a handrail bracket and how to paint stair risers!

Looking for something?

We've been doing this since 2012 so we have a LOT of blog posts!

Search stuff like: Ceiling Projects | DIY Plant Stands | Thrift Flips

Hey there, I'm Sean, the woodworking enthusiast and builder behind CharlestonCrafted.com! Since 2012, I've been sharing the magic of turning raw materials into beautiful creations. I love teaching others the art and satisfaction of woodworking and DIY. I try to inspire fellow crafters to make something extraordinary out of nothing at all.

Gabby says

This looks so awesome!!! What a great transformation.

Keri says

I love this transformation! Who knew you could order balusters for such a good price. Great job!

Megan says

Loving this transformation! Such a big difference!

Erin- Lemons, Lavender, & Laundry says

That change is HUGE! And I never would've guessed it was so cheap to do. Looks amazing! Pinned this earlier because we should definitely do this to our staircase 🙂

Emy says

Your stairs are looking fantastic! I love those new spindles! And what a great price!

Natalie @nelidesign says

It really says welcome to 2017!

Nicely done! And less expensive that I would have thought!

Liz says

Wow, what a change! I need to to this so bad in my house. Now it doesn't seem so intimidating!

Melissa ~ Brown Dog Vintage says

Looks amazing!! I can't believe the difference in the stain and the rails!

Rebecca says

This looks amazing! I cannot believe you were able to do this for under $100!! I am inspired!!

Meredith @ The Palette Muse says

Wow, what a project! They look amazing! I love the style of iron you chose, with that little decorative element. Total transformation!

Wendy says

This makes a huge impact! Nicely done. I love the stain color too:)

Lindsay Brown says

We have been wanting to do this to our banister but gave been nervous! This is great inspiration!

Stephanie says

What a great buy on ballisters! I love how this changed the space!

Brittany Serowski says

It looks fantastic!! I'll see if I can talk my hubs into doing the same!!!

Amber says

I just ordered some and hoping my limited skills can still get as amazing of a transformation! I'm so excited and so scared!

Morgan says

Don't be scared! you can do it! This is a very do-able project. If you post pictures, be sure to tag me 🙂

Gail says

Love the things you're doing. Keep up the interesting and good word inspiring the rest of us!

Sean says

Thanks so much, Gail! We're glad you're enjoying the journey. Let us know what you've been up to!

Kathy Jerman says

Did you check the City/ State code? It looks like they are too far apart a child can get their head in there and get stuck. and yes there is a specific code that pertains to this. NO children in the house, no big deal. When you sell it could be a big deal.

Morgan says

We did not move or change the location or spacing.

Cate says

Updates it from builder grade to luxurious. Beautiful!

Daniel says

Hi! Thanks for this post. Today, we purchased the reciprocating saw and metal-cutting blades, but we're having a really hard time cutting the balusters. The saw quits cutting almost immediately when it makes contact with the metal. And I have the balusters placed between two vices, but it still comes loose. Do you have any best practices? Thank you!

Morgan says

That might depend on the saw you bought and how much power it has. One thing I can think of is to make sure you're cutting with the baluster right up against the stop collar on the saw. If you're further near the end of the saw blade, it will cause vibration and might stop the saw. Also make sure the use good pressure when you're cutting to reduce the vibration.

Jocelyn says

How to determine if you need a flat or angled shoe?

Morgan says

Based on if the base of your baluster will be flat or angled!

Gm says

Hello. I’m interested in doing this project. By code, my spindles need to be no more than 4” apart. If I take out my balusters and replace them with the thinner metal, they are greater than 4” apart. How hard is the process of drilling new shaving holes in the railing and base trim?

Sean says

If your balusters are that much larger and you'd need closer spindles, the problem is going to be the holes you already have in there. It is going to be difficult to drill holes that are properly spaced out among the holes you'll already have in place. Seems to me like they would overlap and would offer no support. Your best bet might be to fill all the holes entirely then start over with new holes. New holes aren't necessarily hard, you just need to ensure that they are completely lined up on top and bottom.

Josue Verona says

Did you need to remove the handrail portion or the newels before sanding and staining?

Sean says

Nope. We sanded in place. If you have any intricate details or curved features, you'll need to just hand sand with flexible paper to get into the grooves.

Robyne says

About to try this. Did you just use glue to hold it in place? The top hole is so much bigger than the baluster.

Sean says

We used hot glue and then later went back and replaced with 2 part epoxy. Epoxy is very strong. Here is exactly what we used - https://amzn.to/2JsCPPp

Kelley Besl says

Want to replace mine too! But I'm afraid there are no holes on the bottom cap to drop the baluster into. It didn't look like your (on the angle) had holes. How did you do the angled balusters?

Morgan says

So we started by just gluing them, but a toddler changed that eventually. We ended up drilling very shallow holes for them to sit in and putting the glue in there to stabilize.

Indre says

Looked perfect before, I really hate seeing people using resources to replace perfectly functioning things just because they're bored 🙁 I think repainting would have done it better and more professional than GLUEING parts of the stairs (unsure how it affects safety).

Morgan says

It was functional before, but that doesn't mean it looked perfect to us. We chose to update those railings for a modern look. You don't need to keep a house looking exactly how it looked the day it was built just because it's functional. To each their own!